3 Things you Need to Know about

Bioproducts

Bioproducts are becoming a great

source of raw material for things we use every day. Using bioproducts has the

potential to be more economically friendly than using fossil fuels. It is important

to know what kinds of materials can be made from bioproducts and how these

processes occur. Three important products

that you have probably used many times include sugar, plastics, and fuel, but what

materials are used to make these products and how are they made?

1. How do we get Sugar from Bioproducts?

Sugar can be obtained from a

variety of bioproducts. Some of these bioproducts

include sugar cane, corn kernels, and corn stover. The bioproduct we use for sugar depends on

the where we are in the world. For us in

the U.S., the sugar making process relies on corn as the main bioproduct

source. The process for retrieving sugar as a product is different for each

source you use, but we will be looking specifically on the process from corn to

sugar.

Corn

begins its process to sugar in the milling stage. In the dry milling stage, the corn is grinded

down in order to expose the starch. A corn slurry is made from a mixture of the

exposed starch and water and it is heated.

Next, amylase is used as an enzyme to break down the starch molecules

into maltose and then another enzyme is used to break maltose into the simple

sugar glucose monomers (Corn Syrup).

2. How do we get Plastics from Bioproducts?

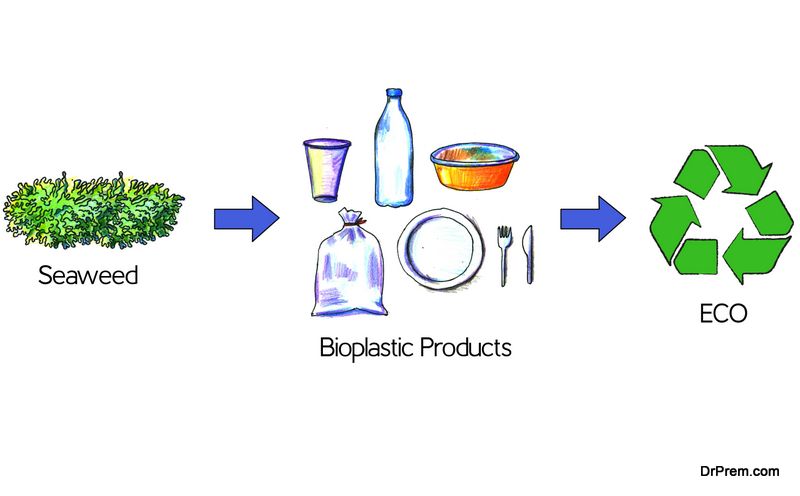

Generally,

the hydrocarbons used to create plastic come from nonrenewable fossil fuels,

but plastic can also be produced from bio renewable materials such as wood

material, oils, starch, and food waste. There

are a variety of bioplastics that can be made such as non-biodegradable, biodegradable,

and compostable. The non-biodegradable bioplastics are made primarily from

sugar. The process to make these bioplastics

from sugar can involve different processes with many similarities. This includes fermenting and distilling sugar

to ethanol. Ethanol is then chemically

reacted to form a version of ethylene. Then

a polymerization occurs. For biodegradable

bioplastics, the process is much different.

The raw materials used to make these plastics include starch, cellulose,

and sugar. Many of these processed involve fermentation and heat applications

(Gibbens).

3. How do we get Fuels from Bioproducts?

In conclusion, bioproducts make up

a huge portion of materials we use in our lives including sugars, plastics, and

fuels. It is vital to know where these products come from and how we can utilize

these products compared to nonrenewable resources. Many people do not realize the

extent of products that can be made from bio renewable resources.

Resources

“Corn Syrup.” How Products Are Made, http://www.madehow.com/Volume-4/Corn-Syrup.html.

Gibbens, Sarah. “What You Need to Know about Plant-Based

Plastics.” Bioplastics-Are They Truly Better for the Environment?,

21 Nov. 2018, https://www.nationalgeographic.com/environment/2018/11/are-bioplastics-made-from-plants-better-for-environment-ocean-plastic/.

McFadden, Christopher. “Seven Cool Biofuel Crops That We Use

for Fuel Production.” Interesting Engineering, Interesting

Engineering, 12 Mar. 2018, https://interestingengineering.com/seven-biofuel-crops-use-fuel-production.

Ogden Publications, Inc. “Fuel From Plants! The Basics of

Biofuels.” Mother Earth News,

https://www.motherearthnews.com/green-transportation/fuel-efficiency/biofuels-zkcz12zsch.